Understanding the Inner Workings of Carbon Fiber Cartridges

Imagine a world where every component of an engine or a high-performance device is lighter yet more resilient, a world where the limits of performance are pushed to new heights. This utopian scenario is becoming a reality with the revolutionary material known as carbon fiber. Carbon fiber is a composite material composed of carbon fibers woven together with a binding resin, offering a unique blend of strength, stiffness, and weight reduction. It has been transforming industries such as automotive, aerospace, and sports equipment, making it a critical component in high-performance applications.

Carbon fiber cartridges, in particular, are not just another piece of hardware; they are at the forefront of innovation, enhancing performance, and pushing the boundaries of what is possible. This guide will delve into the hidden strengths of carbon fiber cartridges, exploring their core characteristics, manufacturing processes, applications, and future prospects. By the end, you will have a comprehensive understanding of why carbon fiber cartridges are revolutionizing various industries.

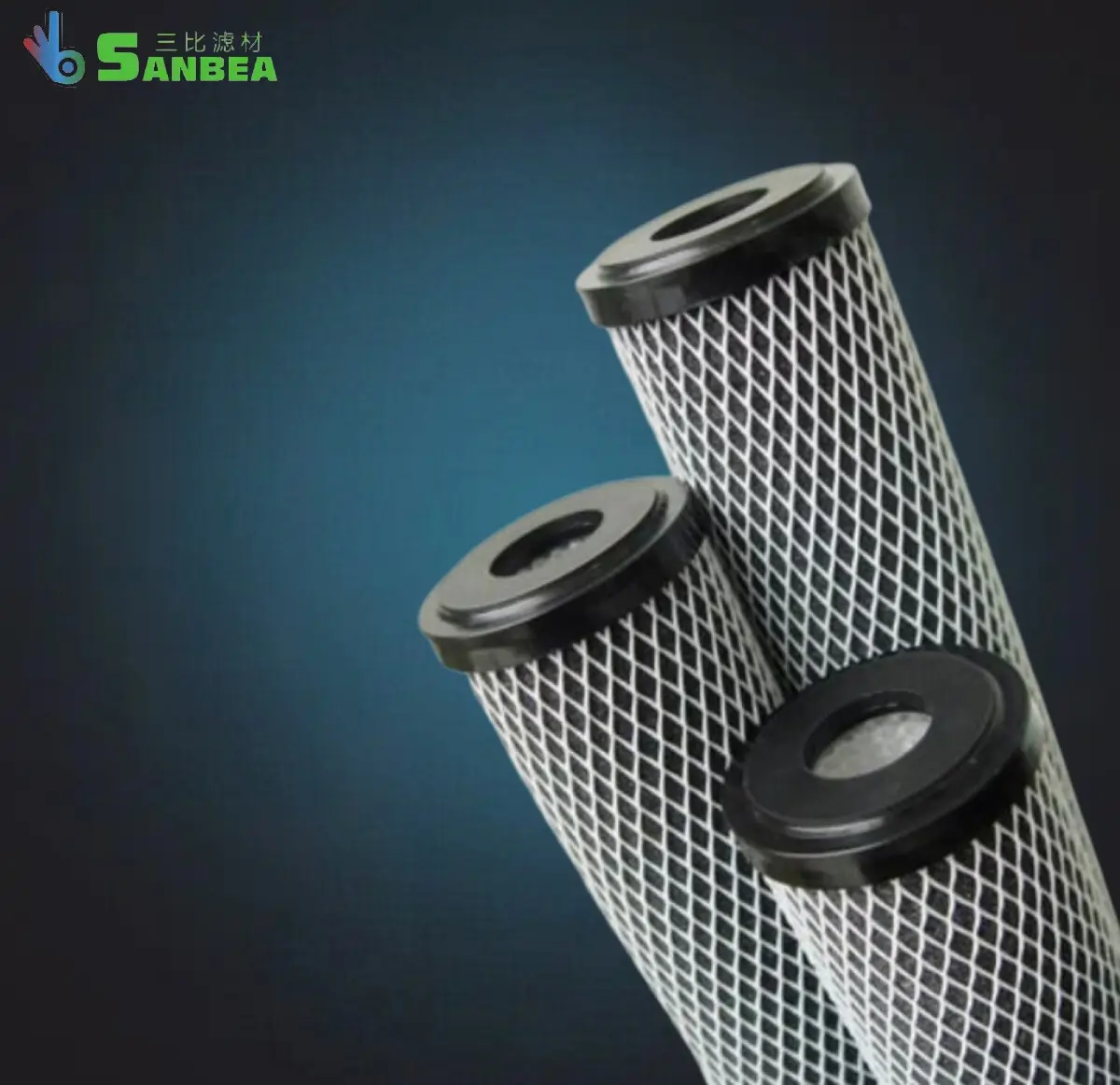

What Are Carbon Fiber Cartridges: Core Characteristics and Composition

Carbon fiber cartridges are specialized components made from a combination of high-performance carbon fibers and a binding resin. The carbon fibers are typically aligned in a way that maximizes their strength and stiffness, creating a material that is both strong and flexible.

The manufacturing process of carbon fiber cartridges involves several intricate steps. Raw materials, such as carbon fibers and resins, are meticulously selected and handcrafted to ensure optimal quality. The carbon fibers are woven into continuous strands, and these strands are then impregnated with a binding resin. The resin-covered fibers are layered into a pre-preg, which is subsequently cured under precise temperature and pressure conditions to form the final product. This process ensures a strong and uniform matrix with exceptional mechanical properties.

Understanding the Manufacturing Process: From Raw Materials to Finished Product

The manufacturing process of carbon fiber cartridges is a multi-step journey that demands precision and expertise. The process begins with the selection and preparation of raw materials, including high-quality carbon fibers and resins, which are sourced from reputable suppliers to ensure consistency and quality.

Next, the carbon fibers are woven into continuous strands using various weaving techniques that ensure optimal alignment and distribution. These woven strands are then impregnated with a binding resin, forming an adhesive matrix that reinforces the fibers and gives the final product its strength and rigidity.

The impregnated strands are layered into a pre-preg, which is carefully constructed to achieve the desired properties. The pre-preg is then subjected to a curing process, where it is heated and pressed under high pressure to bond the layers together. This curing process is critical, as it ensures that the layers coalesce into a uniform and consistent product.

This process is significantly different from the manufacturing of traditional materials like steel, aluminum, or plastic. Traditional materials often require more steps and resources to achieve the same level of performance. Carbon fiber, on the other hand, is more efficient and streamlined, offering a high-quality product with superior properties.

Applications and Advantages: Where Carbon Fiber Cartridges Shine

Carbon fiber cartridges have found applications in a wide range of industries, each benefiting from their unique properties. In the automotive industry, carbon fiber is widely used for springs, suspension components, and structural parts, offering significant improvements in weight reduction and strength. For example, a carbon fiber spring can be 30% lighter than a steel spring while maintaining the same or greater strength, making it a game-changer in automotive tuning.

In the aerospace sector, carbon fiber is a staple in lightweighting projects, where its high strength-to-weight ratio is essential for reducing fuel consumption and improving maneuverability. For instance, the Airbus A350 uses extensive carbon fiber composites in its construction, contributing to significant weight savings and fuel efficiency.

In the field of sports equipment, such as airguns and bows, carbon fiber is used to enhance performance and reduce weight, resulting in improved accuracy and efficiency. A carbon fiber airgun, for example, can be lighter and more responsive, providing shooters with a more consistent and precise shooting experience.

Beyond these traditional industries, carbon fiber cartridges are also finding their way into scientific instruments, medical devices, and even consumer electronics. Their durability and lightness make them an ideal choice for applications where weight and strength are crucial.

The advantages of carbon fiber cartridges are manifold. Their high strength-to-weight ratio allows for significant weight reduction without compromising on strength, making them ideal for high-performance applications. Their durability and resistance to environmental factors, such as humidity and temperature fluctuations, ensure that these components remain functional even under challenging conditions. Additionally, the unique properties of carbon fiber allow for the creation of components that are both flexible and rigid, making them suitable for a wide range of applications.

Comparison with Traditional Materials: A Side-by-Side Analysis

To fully appreciate the advantages of carbon fiber cartridges, it is essential to compare them with traditional materials such as steel, aluminum, and plastic. Carbon fiber cartridges offer a significant improvement in weight reduction while maintaining or even enhancing strength. For instance, a carbon fiber spring can be significantly lighter than a steel spring while maintaining the same or greater strength, making it more efficient and cost-effective.

In terms of cost, carbon fiber cartridges, while initially more expensive, often offer long-term savings due to their durability and efficiency. Traditional materials, such as steel and aluminum, may require more resources and maintenance to achieve the same level of performance, making carbon fiber a more sustainable choice in the long run.

The mechanical properties of carbon fiber cartridges also set them apart from traditional materials. Their high modulus, or stiffness, allows them to maintain their shape under significant stress, making them ideal for applications where rigidity is essential. Additionally, their exceptional resistance to fatigue and creep ensures that these components remain reliable even under prolonged use.

Maintenance and Care: Ensuring Longevity and Performance

Carbon fiber cartridges, like any high-performance material, require proper maintenance and care to ensure their longevity and optimal performance. Proper cleaning and inspection are essential to prevent contamination and damage from environmental factors. Cleaning the components using appropriate solvents and brushes is recommended to remove any dirt or debris that could interfere with their performance.

Environmental conditions, such as temperature and humidity, can have a significant impact on the longevity of carbon fiber components. Proper storage conditions, such as a dry and stable environment, are essential to prevent degradation. Regular inspection is also important to detect any signs of wear or damage early on, ensuring that the components remain in optimal condition.

In addition to environmental factors, handling and operation of carbon fiber components require attention to detail. Avoiding excessive force and impact is crucial to prevent damage. Proper handling techniques, such as using specialized tools and techniques, can help preserve the integrity of these components and ensure their reliability over time.

Future Prospects: Trends and Innovations in Carbon Fiber Cartridge Technology

The future of carbon fiber cartridges is brimming with potential and innovation. As research and development continue to advance, new materials and manufacturing techniques are emerging that could further enhance the performance and efficiency of carbon fiber components. For instance, the development of hybrid materials that combine the benefits of carbon fiber with other advanced materials could open up new possibilities for high-performance applications.

In the realm of manufacturing, advancements in automation and artificial intelligence are revolutionizing the production process of carbon fiber cartridges. These technologies enable higher precision, reduced waste, and faster production times, making the manufacturing process more efficient and cost-effective. Additionally, 3D printing and additive manufacturing are introducing new possibilities for creating complex and customized carbon fiber components, pushing the boundaries of what is possible with this material.

The integration of carbon fiber technology into new industries and applications is another exciting prospect. As more industries recognize the potential of carbon fiber, new markets are emerging where this material can make a significant impact. Whether it is in renewable energy, healthcare, or consumer electronics, the versatility and performance of carbon fiber cartridges are likely to continue driving innovation and progress.

The Future of High-Performance Cartridges

In conclusion, carbon fiber cartridges represent a significant leap forward in material science and engineering, offering unparalleled performance and efficiency in a wide range of applications. Their unique properties, such as high strength-to-weight ratio, durability, and flexibility, make them an ideal choice for industries seeking to push the boundaries of what is possible. From the manufacturing process to their applications and future innovations, carbon fiber cartridges continue to set new standards and redefine the possibilities of high-performance materials.

As the world continues to evolve and demand for innovation increases, the role of carbon fiber cartridges in shaping the future of engineering and technology is only growing more prominent. Their enduring relevance and potential for growth underscore the importance of staying informed about advancements in this field and embracing the opportunities that carbon fiber technology presents.

No. 18, Houjie Section, Houda Road, Houjie Town, Dongguan City, Guangdong, China

Brand name recognition sets sanbea apart in the competitive market.