Maximizing Filtration Efficiency with High Flow Pleated Filter Cartridges

Understanding High Flow Pleated Filters

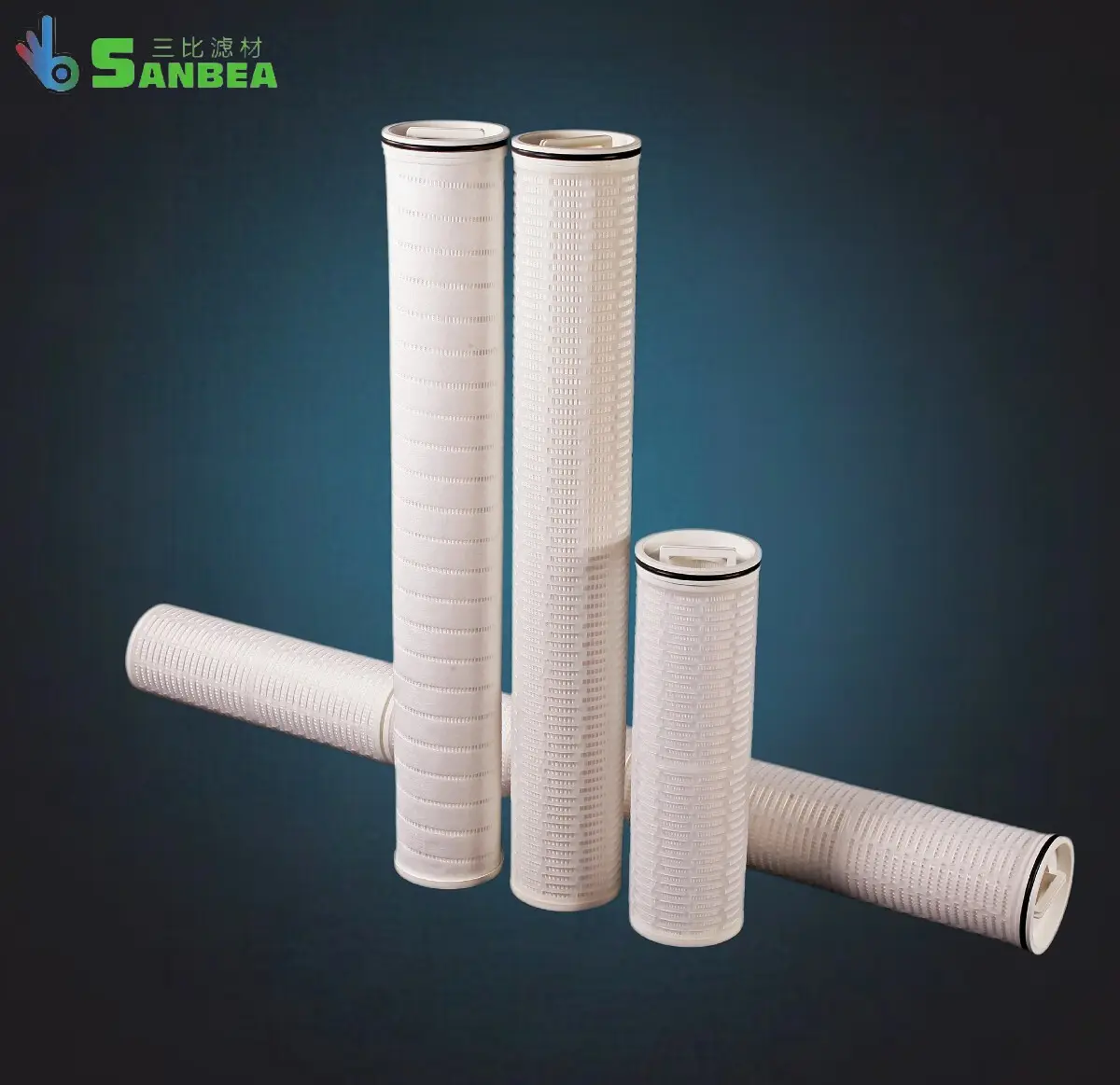

High flow pleated filter cartridges are a cutting-edge solution designed to address the challenges of filtration in industries requiring high flow rates and stringent purity standards. These cartridges feature a unique pleated design, which not only enhances filtration efficiency but also significantly increases the flow capacity compared to conventional filters. The pleated structure allows for a larger surface area for particle capture, ensuring superior filtration performance without compromising on the speed of filtration. This makes them an ideal choice for applications where both high flow rates and effective filtration are critical, such as in water treatment, oil and gas, and pharmaceutical manufacturing.

The Construction and Design of Pleated Filters

The design of high flow pleated filter cartridges is a testament to engineering excellence. The pleats, which are folds in the filter medium, create a more extensive surface area, thereby increasing the filtration efficiency. These pleats are strategically designed to allow for optimal particle capture while maintaining the integrity of the filter medium. The materials used in the construction of these cartridges are selected for their durability and resistance to chemical attack, ensuring long-term performance. Additionally, the structure of the filter is optimized for both efficiency and ease of maintenance, making these cartridges a cost-effective solution for a wide range of applications.

Key Benefits of High Flow Pleated Filters

One of the most significant advantages of high flow pleated filter cartridges is their ability to maintain high flow rates while delivering exceptional filtration performance. This dual capability makes them a preferred choice for industries where both filtration efficiency and throughput are critical. Furthermore, these cartridges are known for their longer lifespan compared to conventional filters, reducing operational costs over time. Maintenance is also simplified, as these cartridges can be cleaned and reused without compromising their performance. Additionally, the lower maintenance requirements make them an environmentally friendly choice, minimizing the risk of contamination and ensuring consistent filtration quality.

Practical Applications of High Flow Pleated Filters

High flow pleated filter cartridges find applications in a diverse range of industries. In water treatment, they are used to remove impurities and contaminants, ensuring the production of clean water. In the oil and gas industry, they are employed to filter out debris and hydrocarbons, protecting equipment and improving extraction efficiency. In the pharmaceutical sector, these filters are used to purify raw materials and ensure the quality of final products. Their versatility makes them suitable for any application where filtration is essential, and high flow rates are required.

Maintenance and longevity of Pleated Filters

Proper maintenance is crucial to maximizing the performance and longevity of high flow pleated filter cartridges. Regular cleaning and inspection are necessary to remove any accumulated contaminants and ensure the integrity of the filter medium. Cleaning can be done using standard methods, such as pressure washing or vacuum filtration, depending on the level of contamination. Proper maintenance not only extends the lifespan of the filter but also ensures consistent filtration performance, making it a cost-effective solution for long-term operations.

Technological Advancements in Filtration Technology

Recent advancements in filtration technology have further enhanced the performance of high flow pleated filter cartridges. innovations such as self-cleaning pleats, which automatically remove accumulated particles, have significantly improved the efficiency and longevity of these filters. Additionally, the development of multi-layer filtration media has allowed for more efficient particle capture, reducing the risk of particle breakthrough. These technological advancements are not only improving filtration performance but also aligning with sustainability goals, making high flow pleated filters a responsible choice for the environment.

Future Prospects and Trends

As filtration technology continues to evolve, high flow pleated filter cartridges are poised to play an increasingly significant role in various industries. The growing demand for sustainable solutions and the need for higher efficiency in filtration processes are driving the adoption of innovative filtration technologies. Emerging trends such as smart filtration systems, which use real-time data to optimize filtration performance, are set to revolutionize the industry. Additionally, the integration of high flow pleated filters into smart manufacturing systems is expected to enhance operational efficiency and reduce waste. These trends underscore the potential of high flow pleated filters to shape the future of filtration technology.

Conclusion

In conclusion, high flow pleated filter cartridges represent a significant advancement in filtration technology, offering a solution that addresses the challenges of high flow rates and stringent filtration requirements. Their design, construction, and maintenance are optimized for performance, making them a cost-effective and sustainable choice for a wide range of industries. As filtration technology continues to evolve, high flow pleated filters are set to play a crucial role in shaping the future of filtration, ensuring efficiency, sustainability, and quality in an increasingly complex world.

No. 18, Houjie Section, Houda Road, Houjie Town, Dongguan City, Guangdong, China

Brand name recognition sets sanbea apart in the competitive market.