High Flow Pleated Filters: A Review of Latest Innovations

Understanding High Flow Pleated Filters

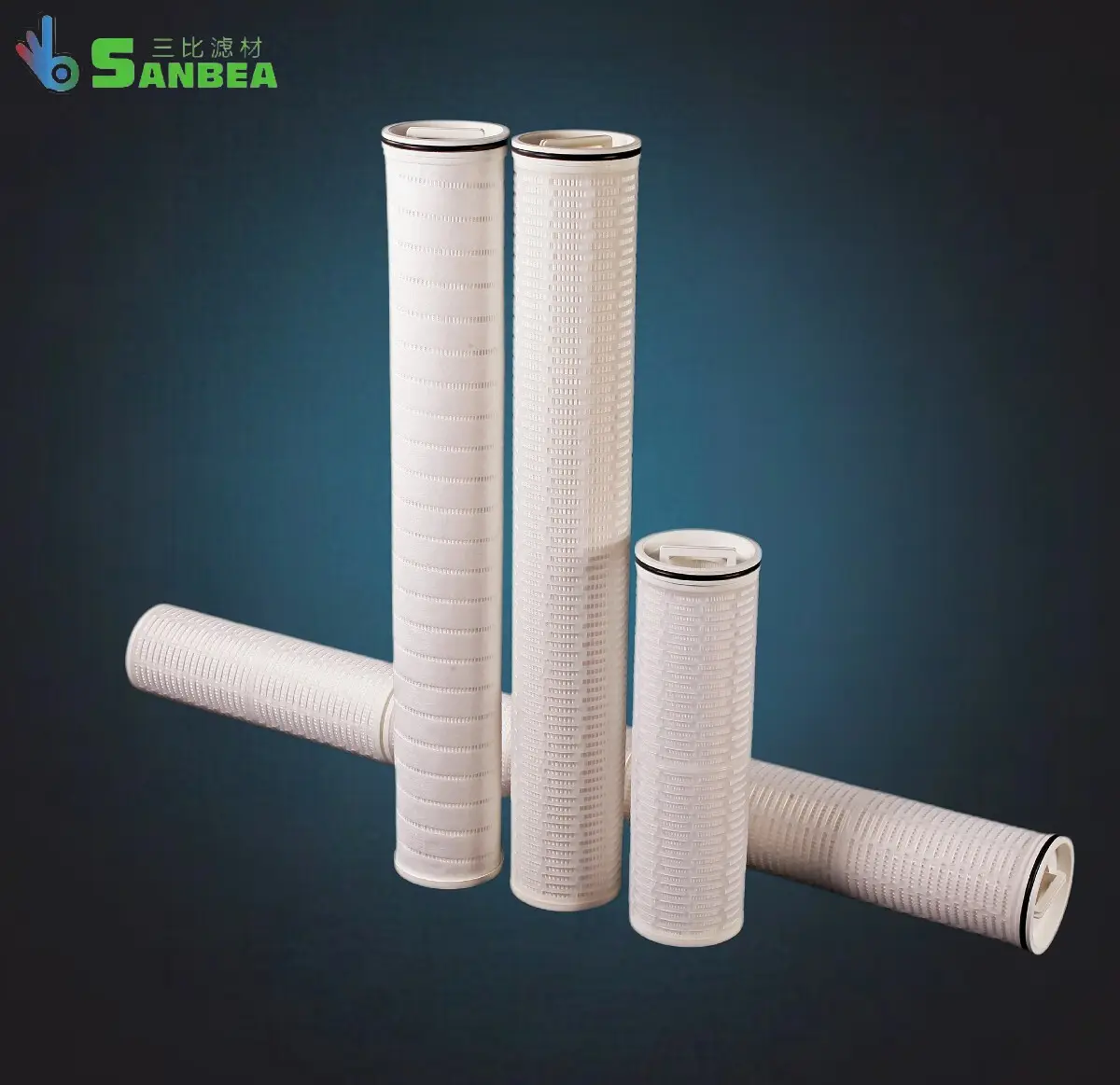

High flow pleated filters are engineered to operate under high flow rates, offering a superior balance between filtration efficiency and throughput. They consist of a filter medium separated by pleats, which increase the surface area for filtration without altering the filter media itself. This design allows for compact installation and reduces maintenance needs. Key components include the pleat angle, which affects flow distribution, and the filter material, which must withstand harsh operating conditions. Porosity is another critical factor, ensuring optimal particle capture while maintaining high flow rates. Understanding these principles is essential for selecting the right filter for specific applications.

Technological Innovations in High Flow Pleated Filters

Recent advancements have revolutionized high flow pleated filters, enhancing their performance and reducing maintenance costs. Innovations include the use of nanofibers, which improve particle capture efficiency and reduce fouling. Advanced pleat designs, such as wedge pleats, offer better flow distribution and longevity. The integration of bio-based polymers in filter media is another significant development, catering to environmental concerns by minimizing chemical usage. Additionally, smart filters equipped with embedded sensors and IoT capabilities are optimizing maintenance and performance in real-time. These innovations are setting new standards in filtration technology.

Implementation of High Flow Pleated Filters in Industrial Settings

Case studies highlight the transformative impact of high flow pleated filters in various industries. In the oil and gas sector, these filters have improved well integrity and reduced blowout risks by efficiently capturing hydrocarbons and fines. In manufacturing, particularly in industries with high particle-laden flows, they have enhanced product quality and reduced downtime. A notable example is a paper manufacturing plant that upgraded to high flow pleated filters, resulting in a 30% increase in production efficiency and a 20% reduction in maintenance intervals. These real-world applications demonstrate the tangible benefits of adopting high flow pleated filters.

Comparative Analysis: High Flow Pleated Filters vs. Other Filtration Solutions

When comparing high flow pleated filters to bag filters and cartridge filters, several factors come into play. High flow pleated filters generally offer higher flow rates and longer lifespans, making them ideal for high-throughput processes. However, they may require more frequent maintenance due to the risk of fouling. Bag filters provide excellent particle capture but are less suitable for high flow applications. Cartridge filters offer flexibility but may not match the efficiency of pleated filters in demanding environments. Considering factors like cost, performance, and environmental impact, high flow pleated filters often provide the best solution for industries prioritizing efficiency and sustainability.

Future Trends and Prospects in High Flow Pleated Filters

Looking ahead, high flow pleated filters are expected to benefit from emerging technologies. The use of graphene-reinforced materials promises enhanced filtration efficiency and durability. 3D-printed filters offer customizable designs for specialized applications. The integration of smart technologies, such as IoT-enabled sensors, will optimize filter performance and reduce operational costs. Additionally, sustainability initiatives will drive the adoption of eco-friendly materials, aligning with global environmental goals. These trends underscore the potential for high flow pleated filters to play an even more critical role in future industrial operations.

The Critical Role of High Flow Pleated Filters in Modern Industry

In conclusion, high flow pleated filters are a cornerstone of modern industrial efficiency, offering a blend of high performance and durability. Their versatility across industries and the ongoing introduction of innovative technologies position them as a vital tool for meeting the challenges of the 21st century. As industries continue to demand higher standards of performance and sustainability, high flow pleated filters will remain indispensable. Encouraging further research and innovation in this field will ensure their continued dominance and drive future advancements in filtration technology.

No. 18, Houjie Section, Houda Road, Houjie Town, Dongguan City, Guangdong, China

Brand name recognition sets sanbea apart in the competitive market.