Common Mistakes to Avoid When Using High Flow Pleated Cartridges

High flow pleated cartridges are essential components in various industrial and domestic systems, designed to efficiently filter, purify, or regulate fluid flow. However, like any equipment, their performance heavily depends on proper installation, maintenance, and usage. To achieve optimal results, its crucial to avoid common mistakes that can lead to inefficiencies, blockages, or even damage to the system. This guide will walk you through the most frequent pitfalls and offer practical solutions to ensure your high flow pleated cartridges operate at peak performance.

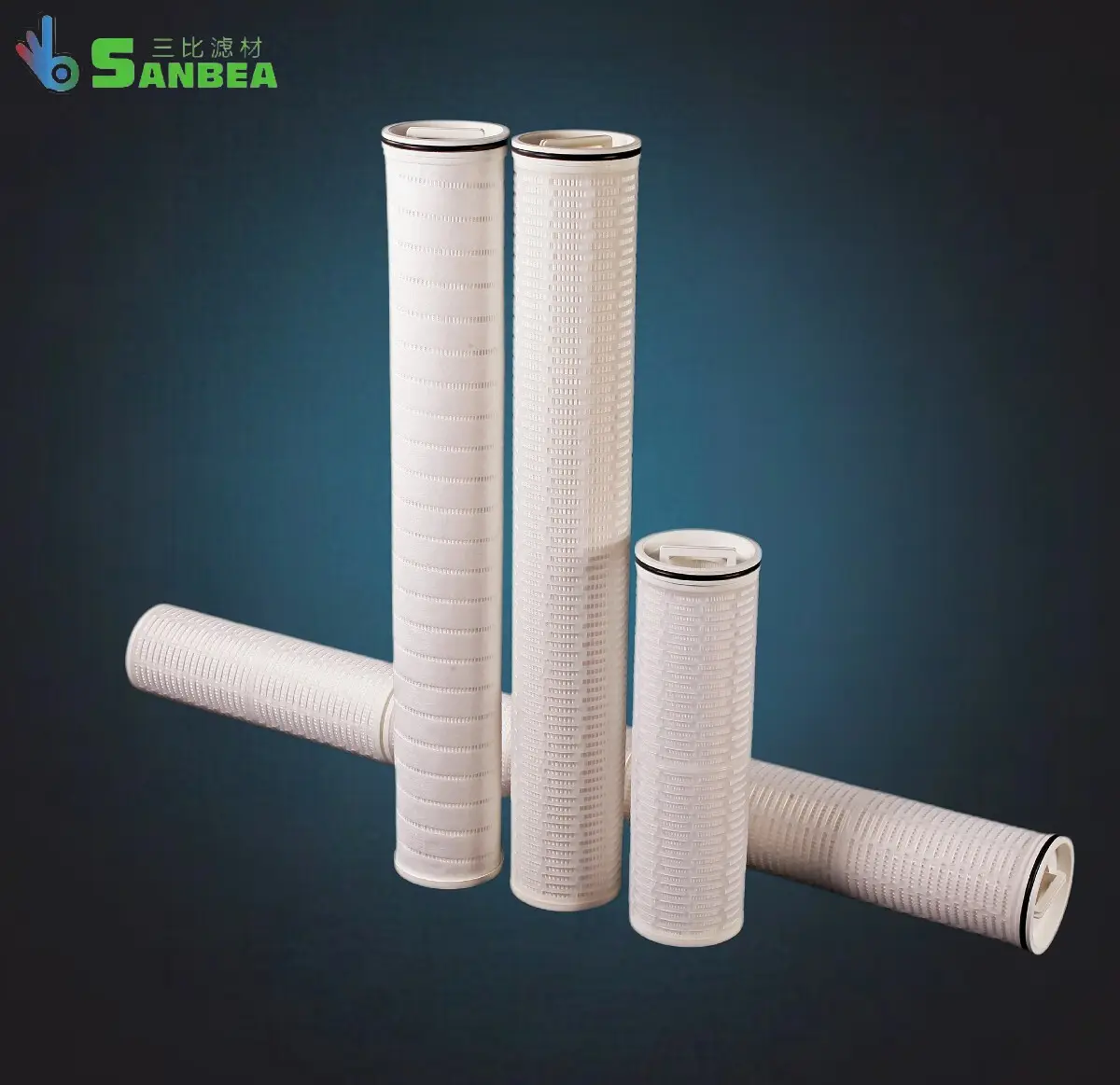

Understanding High Flow Pleated Cartridges

High flow pleated cartridges are a type of filter media known for their ability to handle high volume and high flow rates while maintaining high efficiency. They are widely used in water treatment, oil and gas, chemical processing, and many other industries. These cartridges are designed with a series of pleated filtering media that work in tandem to trap particles, gases, or liquids, depending on the application.

One of the key advantages of high flow pleated cartridges is their compact design, which allows them to fit into tight spaces and maintain minimal system pressure loss. Their high flow capacity makes them ideal for handling large volumes of fluid without compromising performance. However, like any equipment, they require careful handling and maintenance to ensure they perform optimally.

The Importance of Correct Specifications

When it comes to high flow pleated cartridges, choosing the right specifications is paramount. Incorrect specifications can lead to a range of issues, from inefficient filtration to potential damage to the system. Heres why matching your specifications is crucial:

Flow Rate

The flow rate of a cartridge refers to the volume of fluid it can handle per unit of time. It is typically measured in gallons per minute (GPM) or liters per second (LPS). A cartridge with a higher flow rate can process more fluid, making it suitable for high-volume applications. However, a cartridge with an insufficient flow rate may struggle to remove particles or gases effectively, leading to poor filtration results.

Pressure Rating

Pressure rating is another critical factor. It indicates the maximum pressure the cartridge can handle without being damaged or losing efficiency. If the pressure in your system exceeds the cartridges rating, it can cause the media to lose its filtering efficiency, leading to blockages or system failures.

Filtration Requirements

Each application has unique filtration requirements. For example, a water treatment system may require a cartridge with high efficiency for removing particulates, while an oil filter might prioritize blocking large debris. Misunderstanding these requirements can lead to selecting a cartridge that doesnt meet the necessary standards for your application.

Case Study: Incorrect Specifications Leading to Suboptimal Performance

Imagine a scenario where a water treatment plant selects a high flow pleated cartridge with a flow rate of 10 GPM for its system. However, the plant operates with a flow rate of 20 GPM, and the cartridge only has a rating of 15 GPM. This mismatch causes the cartridge to lose efficiency over time, resulting in increased maintenance costs and poor water quality. In contrast, had the plant chosen a cartridge with a flow rate of 20 GPM and a higher pressure rating, the filtration process would have been much more effective.

This case highlights the importance of understanding your systems requirements before selecting a cartridge. It also underscores the potential consequences of underestimating or misjudging these requirements.

Installation Errors and How to Avoid Them

Installation errors are a common cause of issues with high flow pleated cartridges. Proper installation ensures the cartridge is seated correctly, the filter media is aligned, and the system operates efficiently. Here are some common mistakes and how to avoid them:

Improper Sealing

One of the most frequent issues with high flow pleated cartridges is improper sealing. If the cartridge is not seated properly, it can lead to fluid leakage, reducing the cartridges lifespan and compromising its performance. To avoid this, ensure that the cartridge is seated tightly using the manufacturers recommended torque. Oversealing can also damage the gasket, so maintain a snug fit without over-tightening.

Misalignment of Filter Media

The pleated media must be aligned correctly within the cartridge to ensure optimal filtration. Misalignment can cause the media to bunch up or block the flow, reducing efficiency. When installing, carefully straighten the media and ensure it fits snugly within the cartridge. If necessary, use spacers or adjust the packing to maintain proper alignment.

Incorrect Pressure Rating

The pressure rating of the cartridge must match the pressure in your system. Overrating can lead to unnecessary costs, while underrating can compromise filtration efficiency. Always refer to the manufacturers specifications and consider the pressure fluctuations in your system when selecting a cartridge.

Q&A: Tips and Tricks for Proper Installation

- Always follow the manufacturers instructions: Every cartridge comes with specific guidelines for installation. Ignoring these can lead to installation errors.

- Use specialized tools: Employ torque wrenches or ratchets to ensure the cartridge is seated properly without over-tightening.

- Inspect the cartridge visually: After installation, check for any signs of damage, such as bent media or uneven packing.

- Consider professional assistance: If youre unsure about the installation process, consult a professional to ensure proper setup.

By paying attention to these details, you can minimize installation errors and ensure your high flow pleated cartridge operates efficiently.

Ongoing Monitoring and Maintenance

Proper maintenance is essential for the long-term performance of high flow pleated cartridges. Neglecting maintenance can lead to inefficiencies, blockages, or even cartridge failure. Heres how to approach ongoing monitoring and maintenance:

Regular Inspection

Inspect your cartridges regularly to check for signs of wear and tear. Look for caked debris, uneven packing, or damaged media. These signs indicate that the cartridge may need cleaning or replacement.

Cleaning and Cleaning Cycles

High flow pleated cartridges are designed to be cleaned through standard pressure cleaning cycles, but improper cleaning can lead to contamination or damage. Ensure that your system includes a cleaning cycle that thoroughly removes accumulated debris. Contamination can also affect the performance of downstream components, so regular cleaning is a must.

Timing of cartridge Replacement

Replace cartridges when they are significantly worn or when the filtration efficiency drops below the required standards. Overloading the system with worn cartridges can lead to blockages and system failure. Replacement should be scheduled based on the cartridges lifespan and the operating conditions of your system.

Comparative Analysis: Well-Maintained vs. Neglected Systems

A well-maintained system with regular cleaning and cartridge replacement will operate efficiently for extended periods, producing clean output and extending the systems lifespan. On the other hand, a system with neglected cartridges and improper cleaning will experience frequent blockages, increased maintenance costs, and poor performance. The difference in outcomes underscores the importance of ongoing maintenance.

Misinterpretation of Flow Rates and Overloading

Flow rate is a critical parameter, but its easy to misinterpret or misuse. Overloading a cartridge can lead to catastrophic failure, reducing its lifespan and compromising the integrity of the system. Heres how to avoid overloading:

Understanding Flow Rate

Flow rate refers to the volume of fluid passing through the cartridge per unit of time. It is essential to differentiate between nominal flow rate and actual operating flow rate, as they can vary based on system conditions. Overloading occurs when the actual flow rate exceeds the cartridges design capacity, leading to bypass of the filter media and eventual blockage.

Warning Signs of Overloading

Indicators of overloading include a loss of filtration efficiency, frequent blockages, excessive pressure drop across the cartridge, and the need for additional pressure relief. These signs suggest that the cartridge is overloaded and requires immediate attention.

Avoidance Strategies

To prevent overloading, start with the minimum required flow rate and gradually increase it as the systems capacity grows. Always operate within the cartridges recommended flow rate range and consider the systems total flow requirements when selecting components. Monitoring the systems performance and adjusting flow rates as needed can help maintain optimal cartridge operation.

Incorrect Fluid Handling and Contamination Control

The integrity of high flow pleated cartridges depends not only on their mechanical components but also on how they are handled and maintained. Proper fluid handling is crucial to prevent contamination and ensure optimal filtration performance. Heres how to handle fluids correctly:

Fluid Compatibility

Not all fluids are compatible with high flow pleated cartridges. Some materials can cause degradation, alter the filter medias properties, or lead to caking. Always ensure that the fluid used in your system is compatible with the cartridge. Refer to the manufacturers compatibility chart or consult technical documentation for guidance.

Contamination Control

Fluids in industrial and domestic systems often contain impurities, particulates, or gases that can affect the performance of your cartridges. Contamination can lead to caking, reduced efficiency, or even cartridge failure. Implement contamination control measures such as proper fluid storage, filtering of incoming fluids, and regular cleaning of the system to maintain optimal performance.

Best Practices for Fluid Handling

- Store fluids properly: Use dedicated storage tanks for incompatible fluids to prevent cross-contamination.

- Filter incoming fluids: Ensure that any contaminants in the fluid are filtered out before they enter the system.

- Regularly clean the system: Cleaning the system can help remove contaminants that may have become embedded in the cartridges.

- Use appropriate valves and fittings: Ensure that valves and fittings are compatible with the fluids to prevent leakage or contamination.

By adhering to these practices, you can maintain the integrity of your high flow pleated cartridges and ensure their continued performance.

Key Takeaways for Effective Use

High flow pleated cartridges are essential components of many systems, and their proper use requires attention to detail and a commitment to maintaining optimal performance. By avoiding common mistakes in specifications, installation, maintenance, and fluid handling, you can ensure your cartridges operate efficiently and extend their lifespan.

Key takeaways:

- Correct Specifications: Choose cartridges with the right flow rate, pressure rating, and filtration requirements for your application.

- Proper Installation: Seat the cartridge correctly, align the media properly, and use the right torque to avoid installation errors.

- Ongoing Maintenance: Regularly inspect and clean the cartridges, replacing them when necessary to maintain efficiency.

- Avoid Overloading: Monitor flow rates and operate within the cartridges recommended range to prevent catastrophic failure.

- Fluid Compatibility and Contamination Control: Use compatible fluids and implement measures to control contamination to ensure cartridge integrity.

By following these guidelines, you can maximize the performance of your high flow pleated cartridges and ensure the reliability of your system. Remember, a well-maintained cartridge is a key factor in achieving high system performance, so invest in proper care and maintenance.

-

-

2.1Flow Rate

-

-

-

-

-

No. 18, Houjie Section, Houda Road, Houjie Town, Dongguan City, Guangdong, China

Brand name recognition sets sanbea apart in the competitive market.