Understanding the Durability of Carbon Fiber Filters for Long-Term Use

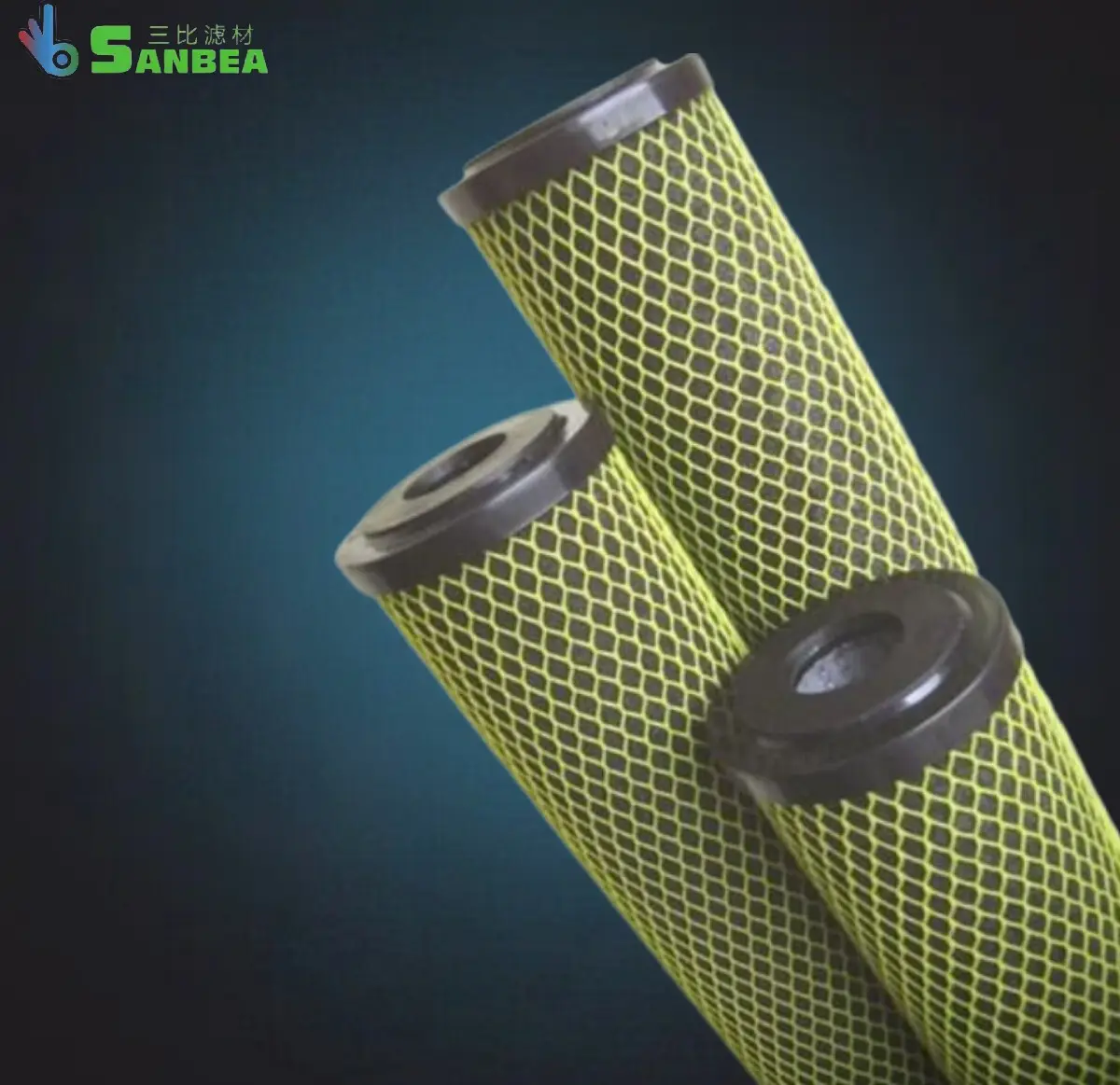

Carbon fiber filters are advanced filtration systems engineered from high-performance carbon fiber materials. These materials are renowned for their exceptional strength-to-weight ratio, making them ideal for filtration applications. Unlike traditional filters made from materials like paper or ceramic, carbon fiber filters utilize a porous structure composed of nanometer-scale carbon fibers. This structure allows for efficient adsorption of impurities, effectively capturing particles such as dust, bacteria, and volatile organic compounds. The filter's material is impregnable, resisting puncture and retaining its integrity even under rigorous conditions.

Compared to conventional filtration methods, carbon fiber filters offer superior efficiency and a longer lifespan. Their lightweight design reduces installation challenges, while their robust structure minimizes the risk of damage from environmental factors. This combination makes them a preferred choice in industries where reliability and sustainability are paramount.

Key Factors Affecting Durability

The durability of carbon fiber filters is influenced by a variety of environmental and operational factors. Environmental conditions such as temperature, humidity, and exposure to chemicals can degrade the filter over time. High temperatures can weaken the carbon fiber material, leading to reduced efficiency and potential failure. Similarly, high humidity can cause the filter's pores to clog, impeding performance. Chemical exposure, whether from cleaning agents or pollutants, can alter the filter's material properties, potentially leading to degradation.

Mechanical stress is another critical factor. Filters subjected to repeated stretching or compression may experience wear and tear, affecting their longevity. The filter's material quality and manufacturing processes are also vital. High-quality carbon fiber materials with consistent pore structure and thickness ensure optimal performance and durability. Proper manufacturing techniques, such as layering and bonding, contribute to a filter's resilience against mechanical stress.

Case Studies: Real-World Applications

Carbon fiber filters have found extensive application in various industries, where their durability and efficiency have been validated. In air purification systems, carbon fiber filters are employed to remove pollutants from indoor air, ensuring a healthier living environment. Their ability to effectively capture dust and odors in large spaces demonstrates their versatility.

In water treatment, carbon fiber filters are utilized for advanced water filtration, removing contaminants such as bacteria and heavy metals. Large-scale filtration systems, such as those used in municipal water treatment plants, rely on these filters for their consistent performance and long lifespan. Additionally, in the food and beverage industry, carbon fiber filters are used to purify water for bottling processes, ensuring the highest standards of safety and quality.

Comparative Analysis: Advantages and Disadvantages

Carbon fiber filters offer numerous advantages over traditional filtration methods. Their high efficiency in capturing particles of various sizes, coupled with their robust design, ensures reliable performance over an extended period. The lightweight nature of these filters makes them ideal for applications where space is a constraint, such as in medical equipment or portable air purifiers.

However, carbon fiber filters are not without limitations. Their relatively high cost and the complexity of their manufacturing process can be barriers for some applications. Additionally, while they are highly durable, they still require regular maintenance and cleaning to maintain optimal performance. Despite these challenges, the benefits of carbon fiber filters in terms of efficiency and longevity often outweigh their drawbacks.

Testing and Validation

Ensuring the durability and performance of carbon fiber filters involves rigorous testing and validation processes. These tests assess the filter's ability to withstand various environmental conditions, including extreme temperatures, humidity, and chemical exposure. Mechanical testing evaluates the filter's resistance to stress and wear, while long-term monitoring ensures the filter maintains its efficiency over time.

Industry standards and certifications play a crucial role in validating carbon fiber filters. These standards provide a framework for evaluating the filter's performance, durability, and safety. By adhering to these guidelines, manufacturers can produce filters that meet the highest quality and reliability standards.

Future Perspectives: Enhancing Durability

As technology continues to advance, so do the possibilities for enhancing the durability and performance of carbon fiber filters. Innovations in material science may lead to the development of new composite materials with even greater strength and durability. Advances in manufacturing processes could also result in more efficient and consistent filter production, reducing waste and improving sustainability.

Additionally, the integration of smart filtration systems could enhance the monitoring and maintenance of carbon fiber filters. These systems might include sensors to track performance metrics and predict potential failures, enabling proactive maintenance and extending the filter's lifespan. Such innovations would further solidify carbon fiber filters as a leading choice for long-term filtration needs.

In conclusion, carbon fiber filters represent a significant leap forward in filtration technology, offering unmatched durability and efficiency for long-term use. By understanding the factors influencing their performance and embracing future innovations, these filters will continue to play a vital role in various industries, ensuring a cleaner and safer environment for all.

No. 18, Houjie Section, Houda Road, Houjie Town, Dongguan City, Guangdong, China

Brand name recognition sets sanbea apart in the competitive market.